Railways

A growing world population in conjunction with increasing urbanization raises the demand for rail-mounted transport systems. This presents a biggest challenge to railway technology, in particular in the growth industries and irrigation. Even in connectivity across the regions, with their dense transportation infrastructure, the market is growing at a disproportionate rate, in particular in the short-distance sector.

The railway segment needs complete connectivity across different divisions like

- Power supply

- Traffic management systems,

- Station facilities management

- Signaling systems

- Rolling stock

- Depot management

Like this it needs various types of power, control, signal, and data communication/network connectivity solutions, and also it is important to ensure automation across the complete system, meet safety and railway standards and regulations. The topic is well known: Railway wires and cables must fulfill demanding national and international standards. In addition to EN 45545-2 these include design standards such as EN 50264 and EN 50306. They define the required sheath and insulation thickness and design and stipulate the mechanical, thermal, fire safety, and chemical tests.

Testing standards that define the requirements for behavior in case of fire are of particular importance. These include

- Flame propagation for a single cable DIN EN 60332-1-2

- Smoke density DIN EN 61034-2

- Content of halogens DIN EN 60754-1

- Acidity/corrosiveness DIN EN 60754-2

- Flame spread of bunched cables DIN EN 60332-3-24/25

- Fluorine content DIN EN 60684-2

- Toxicity EN 50305

These testing standards are part of DIN EN 45545-2: Railway applications – Fire protection on railway vehicles – Part 2: Requirements for fire behavior of materials and components. It defines the requirements for fire behavior. LAPP has fulfilled the technological requirements for satisfying this standard for railway cables.

Cables and wires from LAPP fulfill the key requirements for railway equipment with flying colors. Reliable and safe - up to the highest level defined in EN 45545-2, Hazard Level 3 (HL3). Which is basically fulfill the complete requirement of Railway like

| Brake | Coupler | Battery | Lavatory |

| Driver‘s desk | Train control system | Auxiliary power converter | Lighting |

| Traction converter | Traction motor | Traction Control | Air condition |

| Control cabinets | Blower | Passenger information system | Doors |

Based on decades of experience as a full-service provider for electrical cables, connection solutions and accessories, with its products for the railway industry LAPP offers its customers single-source high-quality solutions in this sector

- IRIS certification

- Its own electron beam cross-linking plant

- Cable types according to EN standards and further standards

- Extensive experience in the rolling stock market

- The shortest delivery times – high warehouse availability

- Small minimum order amounts and packaging

- One-stop-shop for cables, connectors, cable glands, cable protection, marking systems and accessories Customised solutions

- High level of financial stability

- Worldwide service and availability

ÖLFLEX® TRAIN is certified in accordance with the ISO/TS 22163

Our manufacturing facility for the ÖLFLEX® TRAIN is certified in accordance with the ISO/TS 22163, thus operating within the framework of the required processes of the railway industry. ÖLFLEX® TRAIN manufacturing technology Cable insulation products are usually made of thermoplastic materials, mainly consisting of macromolecules. When warmed, the mobility of the molecule chains increases, making the plastic soft and malleable and eventually melting – an exclusion criterion for the use of such materials in railway equipment with its demanding safety and environmental conditions and high-temperature requirements.

To counteract these factors, ÖLFLEX® TRAIN cables are physically cross-linked in our electron beam system using high-energy beams. This gives them significantly improved mechanical and chemical resistance, even at elevated temperatures. However, durability and resistance are important not only at high temperatures. In some climatic zones, cables running along the outside of the railways must be able to withstand temperatures down to -40°C.

Products for Railway Industry

Power & Control Cables

Data Cables

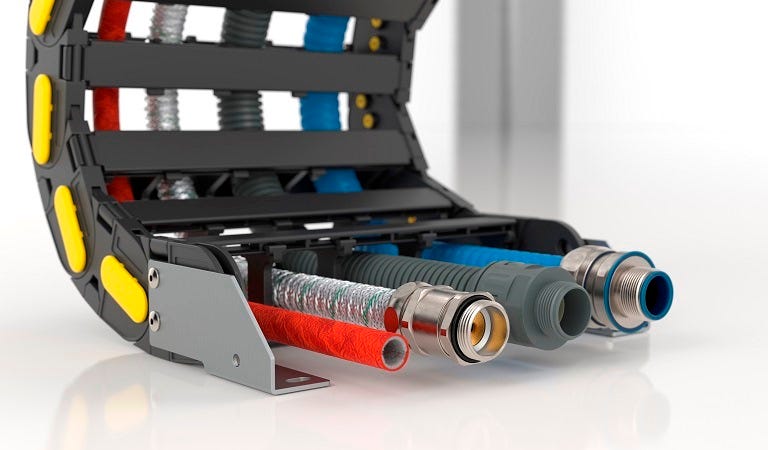

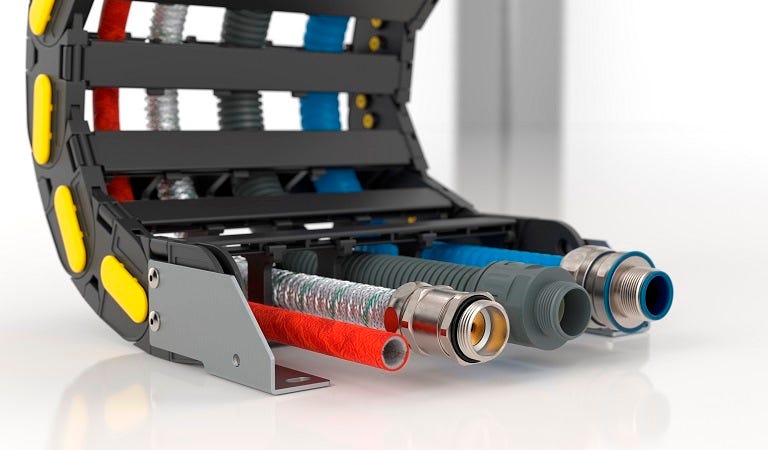

Glands & Connectors

Conduits & Accessories