E-Mobility

The future of mobility is electric. Many of the big countries Government has launched extensive funding activities to support electric mobility – in the form of battery-powered vehicles and fuel cell-powered vehicles fed with hydrogen. The vehicle of the future will be powered electrically – by battery or fuel cell. In 2030, one in three newly registered cars in the world could be an electric car.

Based on propulsion type, the market has been segmented as follows

- Battery Electric Vehicle (BEV)

- Fuel Cell Electric Vehicle (FCEV)

- Plug-In Hybrid Electric Vehicle (PHEV)

- Hybrid Electric Vehicle (HEV)

Based on components (qualitative), the market has been segmented as follows

- Battery Cells & Packs

- On-Board Charge

- Infotainment

- Electric Motor

Based on the charging station type, the market has been segmented as follows

- Normal charging

- Super charging

Challenges on connectivity or charging:

- Stringent rules for installation of charging stations

- Use of vehicle-to-grid (V2G) EV charging stations

- EV charging stations powered by renewable energy

- Lack of standardization of charging infrastructure

- Demand for increased vehicle range per charge

LAPP offers user-friendly charging cables for charging

- At public AC charging points

- At domestic or industrial sockets for infrastructure operators

- At charging stations

- At vehicle manufacturers

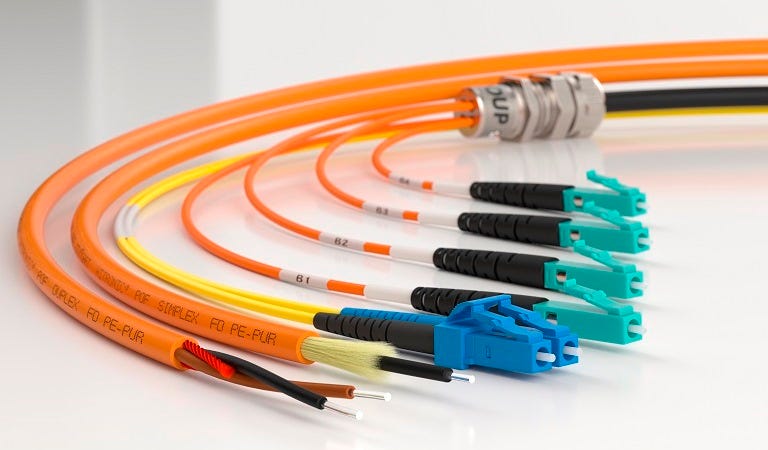

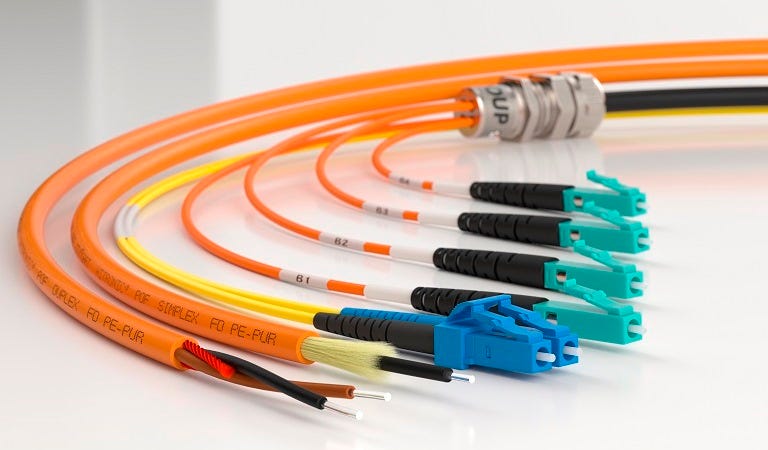

Charging Cables & Plugs

We offer a variety of cable shapes including the LAPP Helix, a charging cable that automatically returns to its original shape after charging. The charging plugs are available in the versions DESIGN and HEAVY-DUTY

- Whereby the robust HEAVY-DUTY line is ideal for particularly demanding applications in the public sector.

- The Mode 2 charging cable for charging at household or industrial sockets gives the electric car driver the flexibility to charge his car from a standard socket if there is no charging station within reach.

Technology Expansion and Manufacturing Development

LAPP meets the technological expansion and manufacturing development and is here to stay and grow. Henceforth smart cabling solutions (slim and light design) with greater intelligence have to be manufactured, as they are the prime facilitators in achieving the objective of interconnecting with low loss.

Broadly, the cables and wires used in these standardized, flexible, temperature resistant, chemical & mechanical resistant, weather-resistant, and safety-oriented with flame-retardant and halogen-free. Therefore there is a constant need for innovation in the industry that will in turn enhance the ability of the industry to develop new products and solutions.

Quality is constantly being ensured in our own highly-modern test centers and internationally unique tests to meet the requirements of the products, applications, and standards. The composition of the group with its own in-house production in the main markets gives our international customers the security of being able to access a large assortment of standard products with the corresponding standards all over the world.

LAPP can fall back on its extensive experience over 50 years of development and manufacturing, and based on this has developed various innovations and a high level of production quality and reliability. Also customized solution without compromising and ready-made products from LAPP systems for Plug and Play.

Products for E-Mobility Industry

Flexible Power & Control Cables

Highly Flexilbe Power & Control Cables

Data Cables