From under the bonnet to scaffolding in construction, the cable tie plays an auxiliary role across industrial, commercial and residential applications. Economical and easy-to-use, this small but mighty accessory has proven immensely useful in fastening and organising jumbled wiring, by means of keeping things secured in the right places.

Originally designed for the aircraft industry in 1937, cable ties have found multiple uses in automotive, gardening to mining and construction. Today, their primary application is protecting electronic products from damage and short circuit. By eliminating the possibility of damaged insulation, they also help to prolong the life span of electronic products, in this case!

Due to its indispensable function as well as ease and contingence of use, the need for this unassuming accessory only continues to grow, fuelled by growth in electronics production and construction activities.

KEY DRIVERS OF CABLE TIE GROWTH

Nylon Market: Set for Rapid Growth

Since it has such a wide spectrum of uses, only a few choice materials offer fitting properties for this multi-purpose accessory, which has varied use cases that place specific demand on mechanical properties including heat, chemical resistance and electrical insulation.

Nylon and stainless steel in particular, have stood out, with the global nylon cable ties market expected to surpass $248.5 million by end 2026[1], thanks to UL-certified nylon cables playing a crucial role in the electronics market.

The more economical of the two, nylon is a synthetic polymer used to make various objects, from the sneakers we wear to fishing lines and cable twist ties. As a class of thermoplastics, nylon’s mix of crystalline and amorphous structures gives it both elastic/flexible qualities as well as rigidity and stiffness, which adds to its ability to withstand high loads.

A CLOSER LOOK AT NYLON 6/6

Nylon 6/6’s Core Properties:

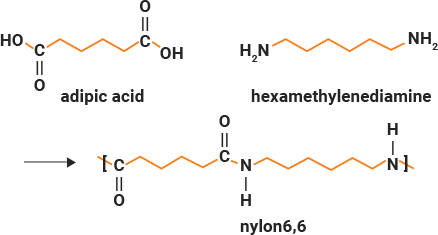

Among nylon variants, the Nylon 6 and Nylon 6/6 are two common variants which exhibit properties best suited for the demands of engineering. Nylon 6/6 is a polyamide formed by six carbons in each reactant as well as in the repeating unit of the chain segment.

Produced by reacting two monomers to form a strong chemical bond, the resulting crystalline structure enhances nylon 6/6 with capabilities of improved temperature sustainability and stiffness. Where extreme performance, reliability and durability are key, the Nylon 6/6's properties such as low creep, good stretch recovery, and higher abrasion resistance make it the clear frontrunner among other materials, and the superior choice for harsh industrial and outdoor applications. It can also be UV-stablised and heat-stabilised for prolonged exposure to excessive temperatures.

Widely applied in applications of safe routing of cables and wire harnesses, it has a projected 30% market share from 2019 to 2026[1].

EXPLORE LAPP CABLE TIE PORTFOLIO

Along with LAPP’s vision of being a one-stop solution for our customers, we will soon offer UL-approved cable ties to work seamlessly in a multitude of cabling applications and requirements, together with our trusted high-performance cabling solutions.

- Simple ratcheting mechanism that enables self-locking

- Resistant to temperatures from -40°C to +85°C

- Resistant to bases, oils, greases, oil derivates, chloride solvents and acids

- UL Listed

- Minimum space required due to the flat binder heads

- Secure ball lock that enables self-locking

- Excellent chemical and acid resistance

- High-temperature resistance up to 500°C

- UL and DNV-approved

CONNECT WITH US

Send your product-related inquiries to lapp.apac@lappgroup.com

and we will get back to you soonest!